Call us now

08045475290

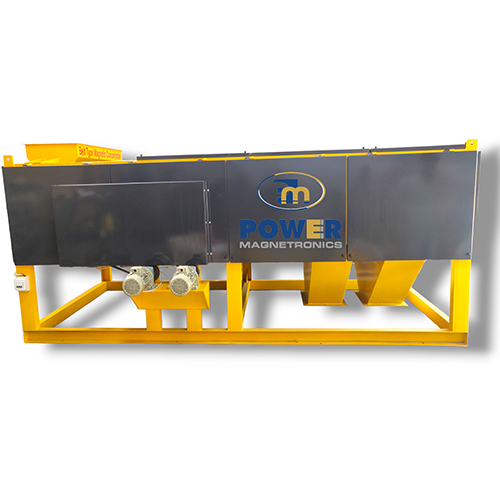

An Belt Type Magnetic Concentrator-Separator is a specialized piece of equipment used in various industries to concentrate and separate magnetic materials from non magnetic materials using a conveyor belt system. This type of separator is particularly effective for the recovery and concentration of valuable magnetic materials from a mixed product stream. They play a crucial role in improving product quality, recycling efficiency, and equipment protection in many processes.

Belt Type Magnetic Concentrator-Separator is available in various sizes and configurations to suit the specific needs of different industries and applications. Power Magnetronics is one of the leading manufacturer of Belt type magnetic concentrator/separator, which are manufactured using the finest quality raw material to ensure quality of products and customers satisfaction. These products are machined according to needs and requirements of customers following international quality guidelines for perfection of high capacity concentrator separators.

Permanent Magnetic Belt Type Concentrator/Separator is extensively used for advancing or concentrating material containing a very high percentage of magnetic or where magnetic/mechanical agitation is required for the separation of many difficult materials. It is perfect for the improving Sponge Iron/Cast Iron borings, Steel/Brassl Aluminium turnings, Chips and for mineral beneficiation application such as the purification of dry ceramic and refractory materials, reclamation of abrasive grains, removal of iron contamination from chemical powders and grains and for many other such applications requiring maximum separation with minimum production loss etc. This ensures the recovery of products in terms of Concentration and with high degree of purity.The sponge iron industries in a particular where the losses of valuable magnetic material with a non magnetic portion takes place, can easily be avoided and thus the sponge iron purity with 99.9% can be achieved.

Working Principle

The Machine works on the induced magnetism principle where by the separation with segregation becomes possible. The material to be treated is fed from the motorized vibratory feeder on to lower belt where after traveling a short distance it comes under the belt conveyor. The upper belt conveyor runs under a series of powerful permanent magnets arranged in such a manner so that the material is exposed during its travel through a number of magnetic fields of alternating polarity. Due to the continuous repetitive agitation of the material nonmagnetic material falls back on to the lower conveyor belt, while the magnetic material is retained on the upper conveyor belt due to the force of magnetic attraction, and it separated as soon as it leaves the magnetic field. The separated material are travelled and deposited into the respective magnetic and non-magnetic discharge chutes. Both the belts are driven by separate geared motor arranged directly to the roll. Belt speed will be decided as per the application.

Application

|

Power Magnetronics

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |