Call us now

08045475290

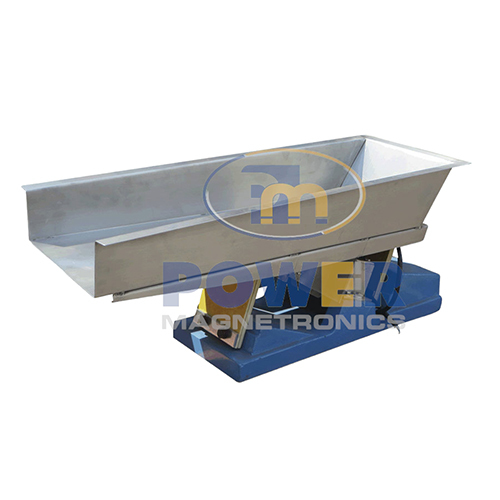

An Electromagnetic Vibratory Feeder is a specialized piece of equipment used in various industries to transport or feed bulk materials, powders, or components in a controlled and regulated manner. These feeders utilize electromagnetic coils to generate vibrations that move the material along a conveying tray or channel. Their ability to provide precise and consistent material flow makes them valuable tools in various manufacturing and processing operations. Electromagnetic Vibratory Feeder is designed to handle a wide range of materials, from fine powders to larger granular materials, and are chosen based on the specific requirements of the application.

Power Mangetronics make electromagnetic vibratory feeder is a new type of feeding equipment widely used in mining, metallurgy, coal, building materials, chemical, electric power, food, and other industries. It is used for transferred the massive, granular, and powdered materials from storage silo, to the stored material equipment continuously or quantitatively. It adapted to automatic batching, quantitative packaging, and automatic control. It is with the advantages of small size, low noise, lightweight, low power consumption, easy installation, and maintenance.

Features

Advantage

In the process of working, you can adjust the excitation force to change and control the flow, and thus it is easy to adjust flow stability, low noise, low power consumption, no material clashing, while the machine is with lightweight, small size, convenient maintenance features, such as it adopts an enclosed structure to prevents dust from spilling and environmental pollution.

|

Power Magnetronics

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |