Call us now

08045475290

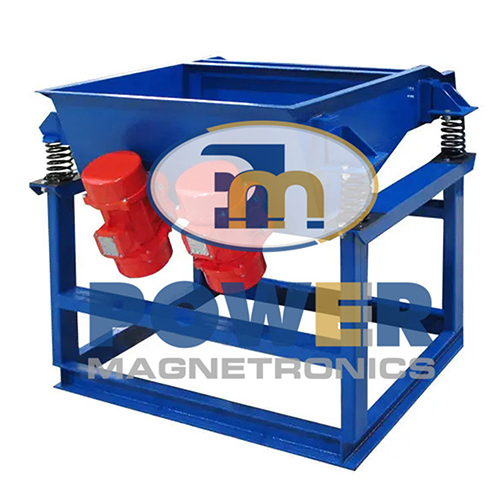

An Vibratory Feeder is a specialized piece of equipment used in various industries to transport or feed bulk materials, powders, or components in a controlled and regulated manner. These feeders use vibration to convey materials, ensuring precise and consistent material flow. The frequency and amplitude of the vibrations can be adjusted using control settings to precisely regulate the rate of material flow. This allows for accurate dosing and feeding of materials. Vibratory Feeder play a crucial role in improving efficiency, product quality, and automation in various manufacturing and processing operations by providing controlled and reliable material feeding.

Vibrating Feeder is a kind of linear-direction feeding equipment. It is used to transfer the large size materials and granular materials from hopper to receiving device uniformly, periodically and continuously in the production line, such as to feed materials into the crusher continuously and uniformly also to screen the materials in the sandstone production line.

A vibratory feeder is a device that uses vibration to "feed" material to a process or machine. Vibratory feeders use both vibration and gravity to move material. Gravity is used to determine the direction, and then vibration is used to move the material. The material is almost always a dry material that unlike a liquid, may not move down an incline without some assistance from the vibration effect. The vibratory feeder comes in many shapes and sizes but all use the same principle, which is to feed bulk material at the top in an uncontrolled form and take material out at the bottom at a controlled and steady rate. The vibration source is a vibration motor. Compared with structure of motor, user can reduce the high maintenance cost of shaft and bearings. The vibration motor also has less wearing parts and user-friendly applications.

Types

Features

Applications

|

Power Magnetronics

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |